The main objectives of this project are:

> develop a model-based prognostic method, integrating FMECA and PRM approaches for intelligent equipment condition prediction,

> create a new MDSS (Maintenance Decision Support System) tool for determining maintenance strategy and managing resources in smart industries, integrating ERP support

> to introduce an MSP (Maintenance Service Platform) tool to share information among the personnel involved.

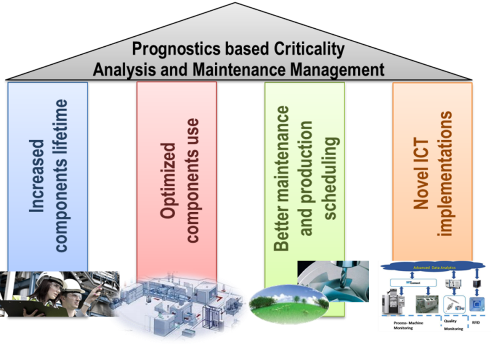

The project approach is able to improve the overall efficiency of enterprises with respect to the following perspectives:

- Increase the availability and therefore the overall efficiency of the equipment (OEE – Overall Equipment Effectiveness) through the increase of mtbf and the reduction of MTTR and MDT.

- Continuously monitor the criticality of system components by performing/updating fmeca analysis at the first implementation or whenever there is a change in the design or composition of the system.

- Build physical models of components that have a higher level of criticality or that their status is difficult to monitor.

- Determine an optimal strategy for maintenance activities

- Creation of a new production task schedule that will optimize overall system performance through an intelligent planning tool, ensuring collaboration between the MDSS, ERP and the Remaining Useful Life (RUL) Estimation Tool.

- To offer, in addition to the traditional data acquisition and management functions in a machine condition monitoring system, robust and customizable data analysis services from a cloud-based platform.

- Develop an intra-factory information service to allow company personnel to be quickly informed of changes in machine tool performance and to be able to easily react to any rescheduling of production and maintenance activities.

The production and maintenance schedule of production lines and entire plants will be carried out with flexibility in real time, in order to operate at the required level of efficiency, optimize resources and plan repairs.